Pumps take a tremendous amount of wear and tear when handling fluids, particularly abrasive or viscous materials. Over time, this can cost organizations large amounts of money and time through extensive and costly maintenance, repairs, and replacements. Discflo can help you optimize your fluid handling to maximize efficiency and decrease downtime.

How Discflo Disc Pumps Set the Bar in Fluid Handling

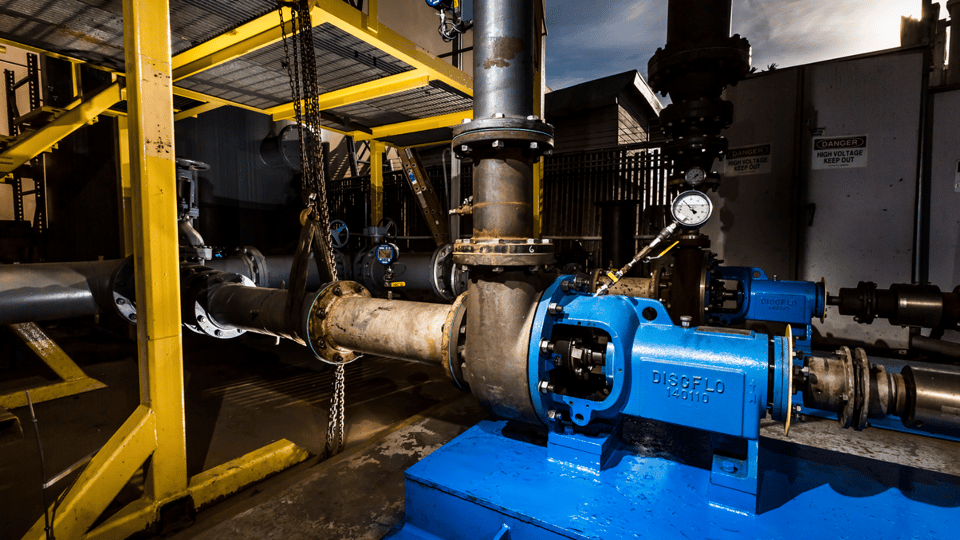

Using our unique and patented discpac technology, our non-impinging pumps require very little or no maintenance. This is because we minimize contact between the pump and the raw material being pumped, greatly reducing the wear on our disc pump components. Not only does this minimize maintenance and product loss, this technology also leads to superior abrasion resistance, gas-entrained pumping ability, and non-emulsifying laminar flow.

We will break down a few applications where Discflo disc pumps have set the standard for fluid handling in tough applications.

1. Abrasives

Discflo disc pumps operate on the principles of viscous drag and boundary layer. The boundary layer offers protection against abrasives, preventing them from grinding or wearing on the surface of the rotary disc assembly. This is true even in abrasive services such as fly ash or Ti02.

Discflo disc pumps operate on the principles of viscous drag and boundary layer. The boundary layer offers protection against abrasives, preventing them from grinding or wearing on the surface of the rotary disc assembly. This is true even in abrasive services such as fly ash or Ti02.

This technology also helps optimize efficiency, as there is no efficiency loss as a result of motor wear. One client reported rocks (1-112-4”) were trapped inside the casing of a disc pump with 2” discharge for several days and the pump continued to operate. The interior of the pump suffered no damage.

2. Viscosity

Discflo’s discpac utilizes the powerful combination of boundary layer and viscous drag to set the standard for pumping viscous materials. Using our non-impinging discpac, viscous fluids easily flow through the pump.

Discflo’s discpac utilizes the powerful combination of boundary layer and viscous drag to set the standard for pumping viscous materials. Using our non-impinging discpac, viscous fluids easily flow through the pump.

Our disc pump becomes more efficient when pumping viscous fluids, easily processing material with viscosities up to 100,000 cPs. At viscosities greater than 350 cPs, our disc pump needs less power than similar-sized centrifugal pumps.

Discflo's disc pump is the only pump that works for a major U.S. paper recycling plant without dilution and stock with consistencies of 8 to 18%.

This ability to handle high viscosities has also helped clients eliminate storage and vacuum systems while saving on water and power as well.

3. Entrained Air and Gas

Our non-impingent technology creates such a gentle laminar flow, bubbles don’t implode. Instead, they pass through the pump like a solid, which results in a pump that can handle up to 70% entrained air or gas. This means no foaming, frothing, or vapor-locking.

4. Superior Product Protection

Shear-sensitive and delicate products often suffer from impinging impellers. Our discpac prevents this problem completely, protecting both your product and bottom line. There is no impact from blades or other impingement devices. In many cases, this can completely eliminate product damage. This has made Discflo disc pumps the pump of choice for many applications in pulp and paper, food processing, chemical manufacturing, and a number of other industries where product integrity is critical.

Shear-sensitive and delicate products often suffer from impinging impellers. Our discpac prevents this problem completely, protecting both your product and bottom line. There is no impact from blades or other impingement devices. In many cases, this can completely eliminate product damage. This has made Discflo disc pumps the pump of choice for many applications in pulp and paper, food processing, chemical manufacturing, and a number of other industries where product integrity is critical.

One of our customers was losing up to 40% of their product due to very delicate and shear-sensitive gelatin fruit spheres. All other pumps they tried to use for the application degraded the product. After installing a Discflo disc pump, they eliminated product damage during pumping.

5. Solids

Discflo disc pumps can move up to 80% solids by volume without clogging. Our unique open design removes close tolerances, resulting in solids being able to pass through without getting trapped or tangled. This includes large and stringy solids.

A chicken processing plant was unable to find a pump that would not clog when handling their poultry waste. We were able to introduce our disc pump as a solution, which moved chicken parts, bones, and even whole chickens without a problem.

How Discflo Disc Pumps Offer Unparalleled Economy

As long as you protect the seal, our disc pump is so durable that you can run it dry. You can even deadhead the discharge and starve the suction at normal operating speeds without damaging the pump, so long as there is seal flushing.

This results in minimal maintenance, fewer repair costs, less downtime, and improved peace of mind.

- Little Required Maintenance

-2.png?width=267&height=150&name=Blog%20Images%20(1)-2.png) Discflo disc pumps reduce spare parts and maintenance requirements by over 90% in many applications. Our pumps do not come with a recommended spare parts list simply because they rarely need them.

Discflo disc pumps reduce spare parts and maintenance requirements by over 90% in many applications. Our pumps do not come with a recommended spare parts list simply because they rarely need them.

- Little to No Downtime

Generally, we only recommend regularly scheduled maintenance for normal bearing lubrication and flushing the seal to maintain pump operation. Experiencing unplanned maintenance due to pump failure is extremely rare when using a Discflo disc pump.

- Ultimate Protection of Shear-Sensitive and Delicate Solids

Our customers consistently report a dramatic yield increase as our pumps virtually eliminate product loss in many applications.

Our customers consistently report a dramatic yield increase as our pumps virtually eliminate product loss in many applications.

- Heavy Duty Shaft

There is less than 0.002-inch shaft deflection under the full-load, full-speed pumping, resulting in an extended life of the shafts, seals, sleeves, and bearings. With proper lubrication, our bearings will last over 80,000 hours.

- Energy Efficient

While our disc pump requires about the same amount of energy for some applications, it can use drastically less power than alternative pumps in viscous applications. This is thanks to the principles of viscous drag and boundary layer and our state-of-the-art discpac.

The Ultimate Fluid Handling Solution

Discflo disc pumps set the standard in fluid handling for the toughest applications. In hard-to-pump applications, our disc pump has a life-cycle cost that is significantly lower than competitors’.

Our pumps are designed to handle viscous, abrasive, air entrained, and shear-sensitive fluid like no other pump. While conventional pumps may require parts and repairs within their first year of service that exceed the initial purchase price, our non-impingement design suffers incredibly little wear. Our customers consistently experience a dramatic reduction in repair and parts requirements and product loss.

The Discflo disc pump is the solution you have been searching for: contact us below to get a quote today.